食品・飲料

市場への製品投入の準備は、生産の稼働率、製品の品質、装置の信頼性、従業員の安全性、持続可能性への認識など、さまざまな要因が影響を及ぼします。厳しい食品安全性要件を満たし、絶え間なく変化する消費者の要求を満たす製品を生み出すには、デジタル化の取り組みを加速させることが不可欠です。

The AspenTech Asset Performance Management suite can help you anticipate issues, with actionable insights enabling you to proactively plan and take corrective measures prior to detecting product quality fluctuations and running assets to failure.

drop in unplanned downtime

increase in process yields

reduction in safety incidents

Finding Hidden Variables

-

● Reduce batch cycle times by 30%

● Reduce off-spec product

Improving Food and Beverage Production Quality and Accelerating Digitalization

What role can digitalization play in production quality and increasing your competitive advantage? By enabling greater visibility into raw materials and process conditions, multivariate analytics soft...

White Paper

Aspen ProMVを使ったプロセス製造

Aspen ProMV provides insight into all the variability issues that plague process manufacturing, and guidance for process engineers, control engineers, and operators to make appropriate process adjustm...

Video

Multivariate Analytics: The Secret to Better Batch Processes

Are you struggling to effectively organize and analyze your data to troubleshoot bad batches? Multivariate analytics will quickly deliver insights that can increase batch quality, yield and throughput...

White PaperCreating a World That Doesn’t Break Down

-

● Reduce equipment downtime 10-20%

● Reduce reactive maintenance costs by 30%

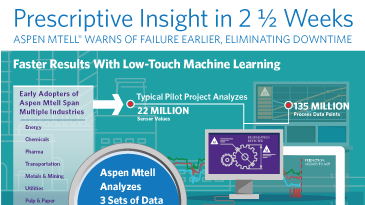

Prescriptive Insight in 2 ½ Weeks

View this infographic to see how prescriptive maintenance early adopters are reducing downtime and improving reliability – with results in as little as 2 ½ weeks.

Infographic

Aspen Mtell® Brochure

Aspen Mtell uses predictive maintenance technology to deliver the earliest, most accurate warning of equipment failures—enabling companies to increase safety, improve asset performance, and reduce emi...

Brochure

White Paper: Seeing Into the Future With Prescriptive Analytics

Discover how to predict equipment breakdowns and perform prescriptive maintenance using a new approach to asset performance management. In this white paper, learn how nine early adopters of prescripti...

White PaperProviding Decision Agility

-

● Save 5% on CAPEX expenditures

● Increase production by 3%

ARC View: Aspen Fidelis Reliability Software Quantifies Financial Benefits Across the Plant Lifecycle

In this report from ARC Advisory Group, learn how Aspen Fidelis Reliability analyzes the impact of variables such as equipment capacities, design configurations, operating logic and more in order to e...

Report

Aspen Fidelis Reliability: Providing Confidence to the Process Industries

Eliminate the guesswork with reliability modeling that quantifies risk.

Brochure

Maximize Safety, Sustainability and Productivity by Turning Unplanned Downtime Into Planned Downtime

Unplanned downtime has wide-ranging impacts that affect more than just a plant’s productivity and profitability. Forced shutdowns also have a major impact on plant and personnel safety, as well as gre...

Executive Brief