Aspen Shell & Tube Exchanger™

Identify energy and capital saving opportunities through designing and rating shell and tube heat exchangers.

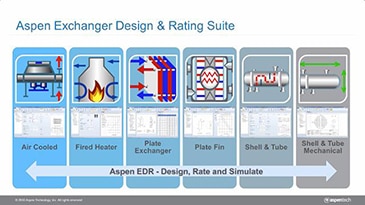

Part of AspenTech’s Comprehensive and Rigorous HX Modeling Solution

Save on Energy and Capital Costs

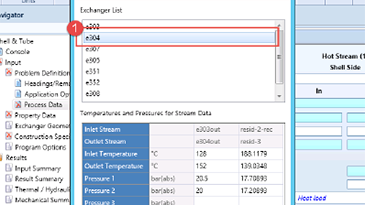

Design and rate shell and tube exchangers using Aspen Exchanger Design & Rating™ to identify the most economic design selection and save significant energy and equipment costs.

Understand Sitewide Process Impacts to Shell and Tube Exchangers

Leverage seamless integration with simulation tools including Aspen HYSYS® and Aspen Plus® to understand equipment design and performance in conjunction with system-level process design.

Accelerate Time to Market

Integration with Aspen Shell & Tube Mechanical™ facilitates better collaboration between thermal and mechanical design groups for shell and tube heat exchangers, achieving faster design turnaround.

Designs You Can Trust

Proven modeling technology based on proprietary theoretical models and correlations backed by over 40 years of experimental study. Easily validate design with in-product access to source methods, models and data.