Many manufacturing companies rely on third-party manufacturers to help them with the manufacturing, storage, handling and transportation of their products under their label or brand name. These third parties are essential in many industries to help companies lower their manufacturing and supply chain costs and meet demands on time. In the chemicals industries, these contractors are often referred to as “tollers” and they are vital in an industry that requires expensive manufacturing facilities and handling hazardous materials to make products that are high-quality and delivered on time.

To keep processes running smoothly, tollers need to be in contact with their client company to ensure they always have the latest information regarding the materials and demands they need to manufacture, package or ship. However, maintaining this tight level of coordination between manufacturing and supply chain teams at two different companies can be challenging.

One AspenTech customer, a chemicals producer, needed to improve collaboration, visibility, and alignment with their tollers. A significant portion of their finished products packaging is contracted out to tollers. In addition, because this is the last step in their production process, the tollers often ship out the final products to the chemicals manufacturer’s end customers. To meet these responsibilities, this customer’s tollers needed to know when materials would be shipped from the contracting client’s sites and when they were expected to arrive at the toller’s site. They also needed to know considerable order-specific information, such as the customer’s name and ship-to location, packaging type, labelling requirements, quantities and expected delivery dates. Additionally, the tollers needed to be able to quickly reach the chemicals producer to ask any questions, gain clarification or to report any issues and shipment delays. Yet another challenge for this customer was how best to communicate this information to its tollers in an easy, consistent way that reduced the likelihood of misunderstandings and avoided costly mistakes.

Fortunately, this customer was already using Aspen Plant Scheduler™ to create and update their production schedules, and all these details required for the toller were already included in their schedules. In addition, the customer was also using Aspen Schedule Explorer™ to share the latest published version of the schedule with their employees, and they realized that because this solution is designed to promote schedule visibility and facilitate collaboration around production and supply chain execution, it would be an ideal tool to help them improve communication with their tollers.

While Aspen Schedule Explorer provided full schedule visibility, for privacy reasons, the customer could not share the entire end-to-end schedule with their tollers and needed to limit visibility to only the parts of the schedule relevant to each toller’s scope of responsibility. They needed a way to easily choose which parts of the schedule their tollers could see in Aspen Schedule Explorer while still allowing their internal users to access the full end-to-end schedule.

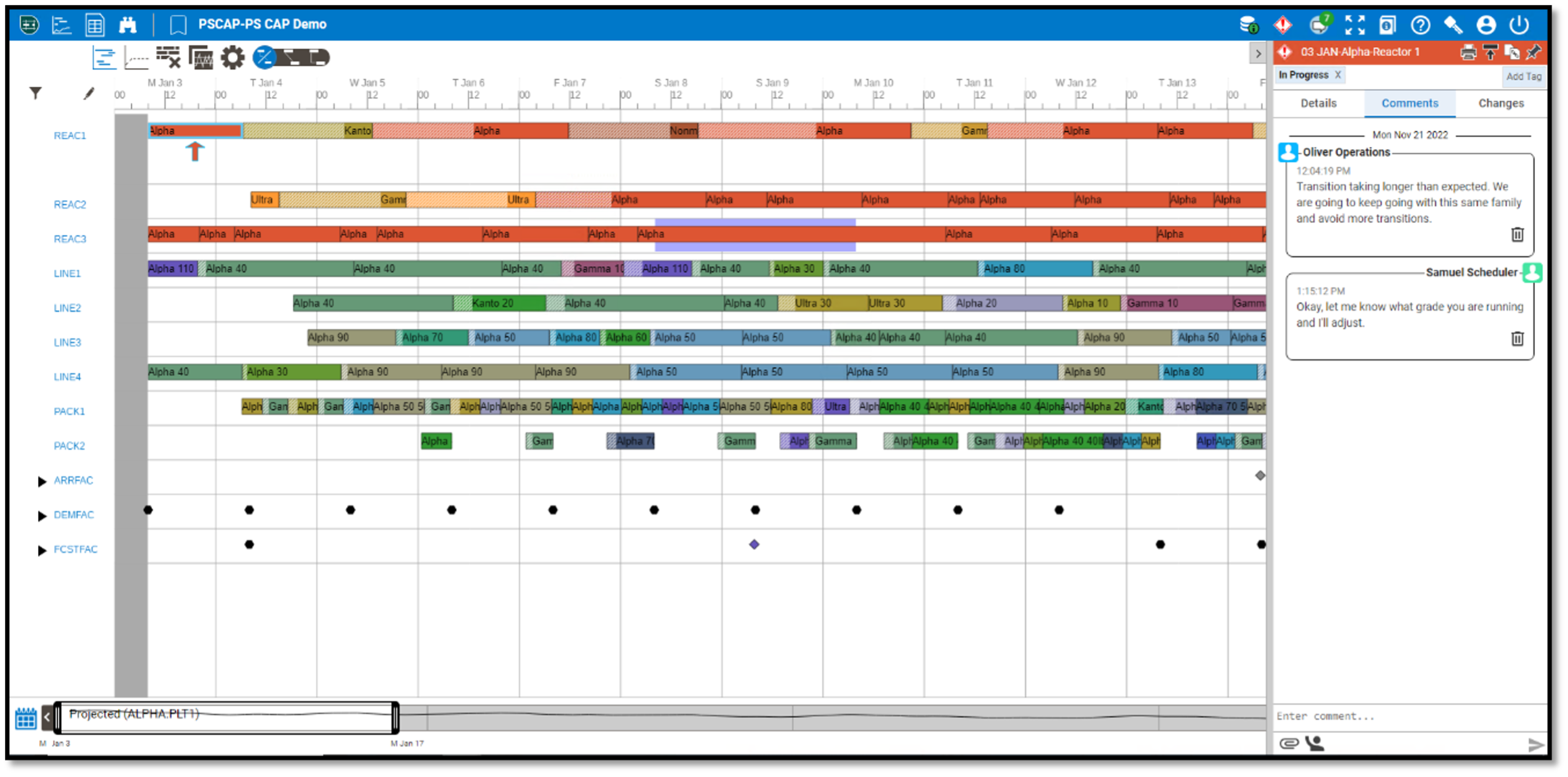

The Gantt chart illustration in Figure 1 below was created by Aspen Schedule Explorer specifically for tollers. Each row represents a critical supply chain activity, stage of production, or piece of equipment (usually referred to as a “facility”). Expected arrivals of incoming materials and targeted times for shipping outbound materials to meet internal and/or external orders were also included as rows. Moving from left to right on a given row showed the upcoming scheduled activities, visualized as colored blocks.

All the details the customer’s tollers needed to complete their steps of the process were included in the individually scheduled activities on the Aspen Schedule Explorer Gantt chart, including quantities, shipping dates and customer information.

Figure 1: Aspen Schedule Explorer – A Collaborative Digital Manufacturing Hub

Improved collaboration, visibility and alignment with aspenONE V14

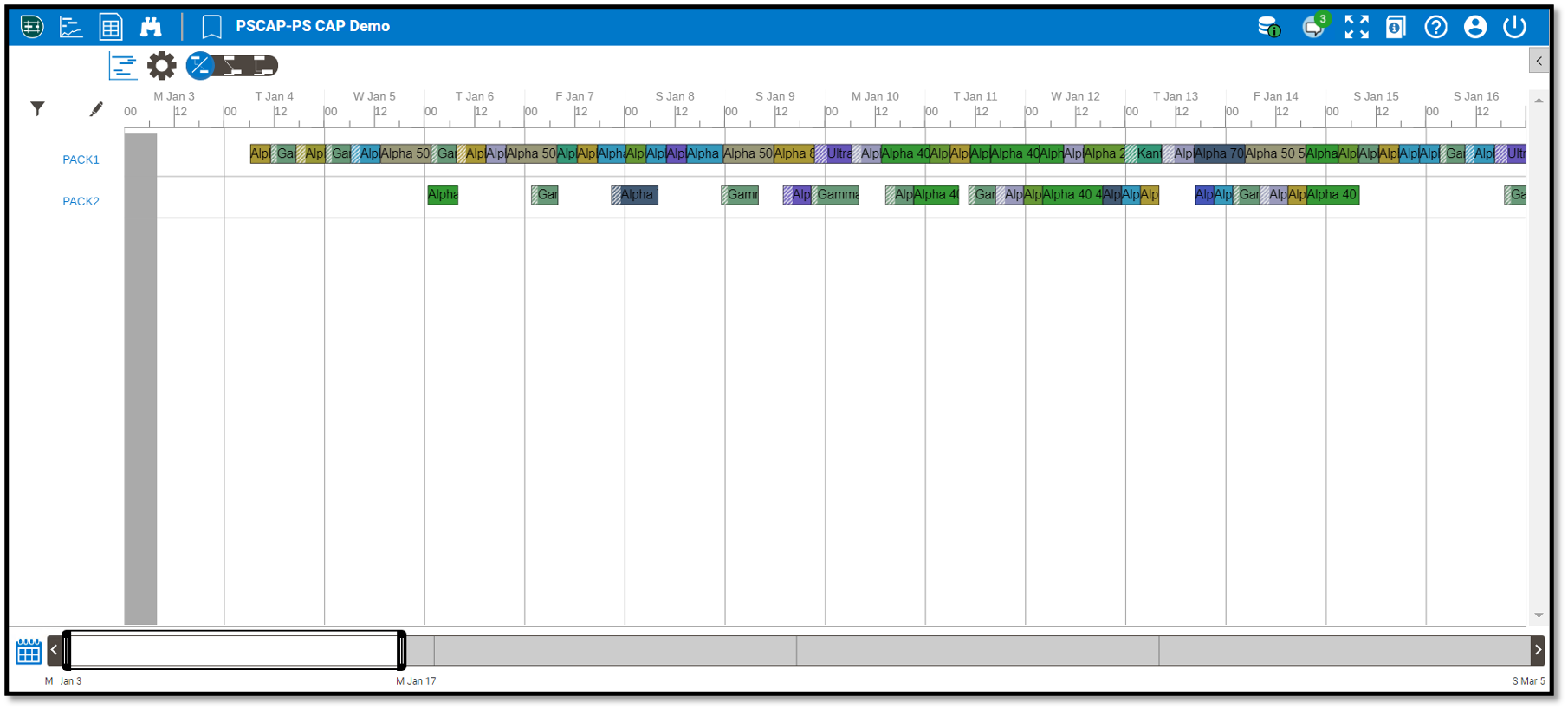

With AspenTech’s launch of aspenONE V14 late last year, new capabilities are available in Aspen Schedule Explorer, including the ability for administrators to limit which facilities on the Gantt chart certain users can see. The new feature, called “restricted facilities,” is simple to manage without making any changes to the Aspen Plant Scheduler model or the schedule that is published to Aspen Schedule Explorer. The Aspen Schedule Explorer administrator can add a new user and set their permissions—including which facilities they are allowed to see—within a few minutes. Additionally, efficiency is streamlined for the scheduler. For example, users can now publish one version of the schedule, rather than splitting the facilities into different schedules (for different tollers) and publishing each individually, depending on user preference.

Figure 2: Users of the newest version of Aspen Schedule Explorer are given a limited view to ensure they have access to the information they need.

With the latest version of aspenONE, toller employees now can be given privileges to access restricted views of the schedule in Aspen Schedule Explorer so they always have the most recent version of the schedule and can use the collaboration capabilities to send messages to their client. They can also see other discussions that the scheduler and production team may have had about the products that are being sent to them for packaging, reducing the odds of packaging errors caused by lack of communication from the client company. Furthermore, the contracting client has improved visibility to their overall process, as they can easily see the full scope of their production, including in-house production and their network of third-party contractors.

Visibility into production is critical for helping production and supply chain schedulers meet their goals, and visibility of the schedule is critical for operations personnel to keep manufacturing running smoothly. When third party tollers are involved in the process, ensuring everyone has the visibility they need can be challenging due to the communication required between different companies. Aspen Schedule Explorer, part of aspenONE V14, can help chemicals manufacturers improve collaboration with their tollers.

.png?h=250&w=975&la=en&hash=E6F0751BAD0DD3B73C441EB30EA05C2D)

Leave A Comment