Aspen ProMV®

Get early and accurate warnings for process health, providing insights to prevent off-spec production, maintain efficiency and rapidly optimize operations.

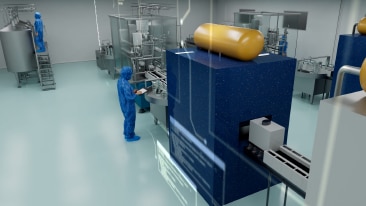

Creating a World without Process Interruptions

Focus on the Critical

Simplify the Complex

Optimize and Troubleshoot Proactively

Related Content

Increase Process Efficiency and Product Quality with Real-Time Data Analytics

Process industries like bulk chemicals, specialty chemicals and pharmaceuticals strive to optimize production processes with existing resources and data to remain competitive and profitable. By implem...

Video

Top Diesel and Naphtha Producer Uses Product and Process Quality Analytics to Reduce Flaring, Emissions

ORYX GTL Limited is a gas-to-liquids (GTL) diesel and naphtha producer located in Doha, Qatar. The company is committed to reducing its carbon production through the minimization of flaring. By implem...

Case Study

Improve Process Efficiency and Product Quality with Aspen ProMV®

For chemical and petrochemical producers, reducing emissions and minimizing disruptions to process requires analyzing and monitoring vast amounts of disparate process data. Learn how Petrocuyo, Braske...

Video

How Braskem Idesa Increased Reactor Uptime by Over 20% Using Existing Data and Resources

In this case study, learn how Braskem Idesa used Aspen ProMV™ to proactively identify and correct for conditions that historically led to high reactor fouling.

Case Study

How Petrocuyo Projects a 60% Reduction in Downstream Treatment Costs

Reprocessing off-spec product is a common, yet costly practice for companies as it uses up materials and increases production time. With first-time, on-spec quality at an unacceptably low level, Petro...

On-Demand Webinar

Polymers Producer Uses Digital Process Analysis to Reduce Costs and Advance Sustainable Operations

A polymer producer that specializes in the production of raw materials for the plastics industry, including polypropylene, polyethylene and masterbatch, needed a solution that would allow them to achi...

Case Study

Aspen ProMV Brochure

Aspen ProMV helps you find the real underlying sources of variation in production processes. Learn how companies such as FMC Corporation and Mitsubishi Chemicals are using this software to stabilize q...

Brochure